Hendersonvilles Service Line Inventory, Compliance with EPA's New Lead and Copper Rule Revisions and Improvements

In 1991, the Environmental Protection Agency (EPA) implemented the Lead and Copper Rule (LCR) to control the presence of lead and copper in drinking water. In 2021, the EPA updated this rule, known as the Lead and Copper Rule Revisions (LCRR), which strengthens regulations to better protect children and communities by reducing lead in drinking water.

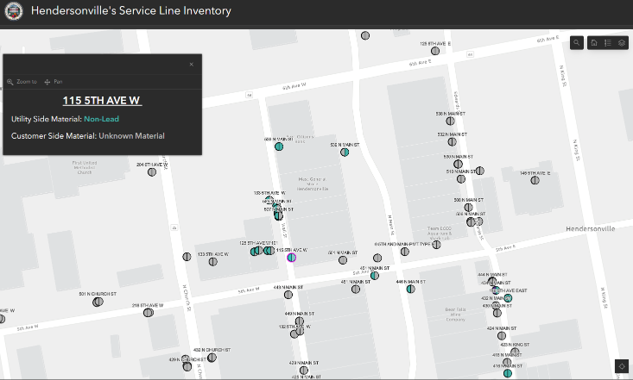

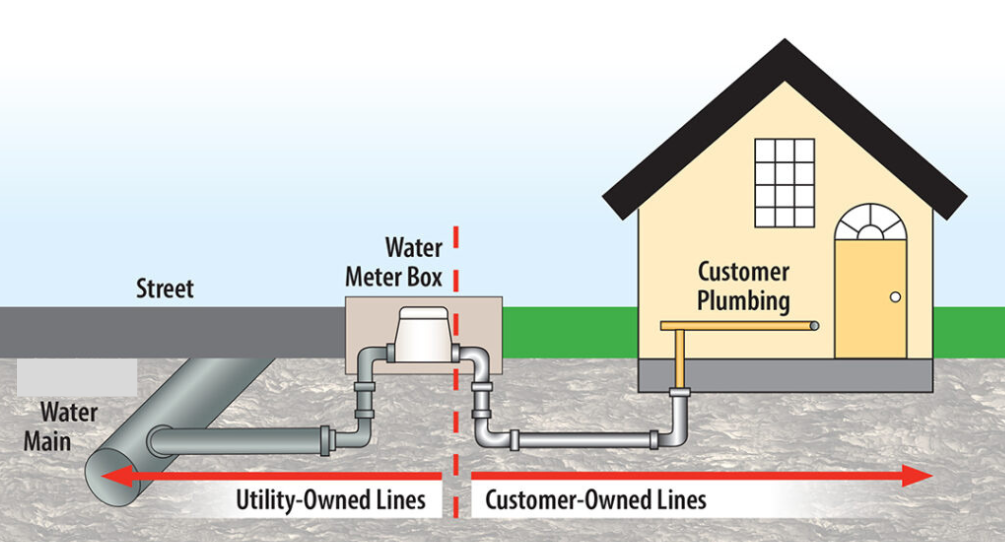

The LCRR requires water utilities nationwide to increase tap water testing and create a service line database to identify the presence of lead pipes in water systems, including elementary schools and daycares. Service lines carry water from the public water mains into homes and buildings, with ownership changing at the water meter. To view our inventory, please see the link on the right side of the screen.

How to Use the Hendersonville Service Line Inventory Map

Watch an overview on the City of Hendersonville's compliance with the EPA's LCRR:

Actions the Utility is taking to reduce lead exposure

The Hendersonville Water Department is committed to protecting the community’s health by delivering safe water. We have monitored lead and copper levels in our water since 1991 and have consistently met EPA standards. Learn more about Hendersonville's water quality efforts.

To ensure water quality meets or exceeds all EPA regulations, we regularly test water at our treatment facility and throughout the system. Lead is not present in our water sources or in our drinking water when it leaves the treatment facility and travels through our lead-free distribution pipes. The Safe Drinking Water Act of 1986 banned the use of lead in plumbing materials, therefore homes built before 1986 are more likely to have lead solder, pipes, and fixtures. Lead may enter drinking water primarily through corrosion in service pipes made of lead, or other plumbing materials that contain lead such as through corrosion of lead solder.

To reduce corrosion, we use best management practices at our Drinking Water Treatment Plant, including adjusting pH and adding a small amount of orthophosphate to create a protective barrier between pipes and water. These practices help minimize corrosion in water lines and household plumbing.

The full LCRR and Lead and Copper Rule Improvements (LCRI) can be found on the EPA’s website at EPA's LCRR and LCRI page. These revisions aim to achieve a 100% lead service line replacement nationwide within the next 10 years, and we are committed to doing our part.

You are protected!

Lead is not present in our source water, nor is it in the water coming from the water treatment plant. Lead can come from plumbing materials that contain lead. A few examples of potential sources of lead are older style faucets made with lead, copper pipes with lead solder, and a lead service line. (We currently have no known lead pipes!!) When these pipes corrode, they can lead lead into drinking water. At the water treatment plant we corrosion control methods to prevent pipes from corroding. We use a pH adjustment, and orthophosphate, which binds to pipes to prevent corrosion.The lead pipe on the left is coated to prevent corrosion. The lead pipe on the right without the coating shows the water dissolved the lead from the pipe.

Orthophosphate is a USDA food grade additive. Phosphate is the second most abundant mineral in the human body after calcium. The amount of phosphate in a quart of treated drinking water is 100 times less than the amount found in the average american diet, and it is found in milk and soda drinks. You would have to drink 10-15 quarts of water to equal the amount of phosphate in one can of soda!

Public vs. Private Water Service Line Responsibility

Your home's water supply system consists of various pipes, parts, and fittings/soldering. Some components are owned by you, the homeowner, while others are maintained by the City of Hendersonville.

- City Responsibility: The city maintains the water main, hydrant lines, water meters, and the section of the water service line connecting the main to the meter.

- Homeowner Responsibility: Homeowners are responsible for the portion of the service line connecting the water meter to the home, as well as all internal plumbing.

What can I do if I am concerned about lead exposure in my drinking water?

Protecting our community from lead is a shared responsibility. Below are recommended actions that you may take, separately or in combination, if you are concerned about lead in your drinking water. The list also includes where you may find more information and is not intended to be a complete list or to imply that all actions equally reduce lead in drinking water.

- Use filters properly. Using a filter can reduce lead in drinking water. If you use a filter, it should be certified to remove lead. Read any directions provided with the filter to learn how to properly install, maintain, and use your cartridge and when to replace it. Using the cartridge after it has expired can make it less effective at removing lead. Do not run hot water through the filter. For more information on facts and advice on home water filtration systems, visit EPA’s website.

- Clean your aerator. Regularly remove and clean your faucet’s screen (also known as an aerator). Sediment, debris, and lead particles can collect in your aerator. If lead particles are caught in the aerator, lead can get into your water.

- Use cold water. Do not use hot water from the tap for drinking, cooking, or making baby formula as lead dissolves more easily into hot water. Boiling water does not remove lead from water.

- Run your water. The more time water has been sitting in pipes providing water to your home, the more lead it may contain. Before drinking, flush your home’s pipes by running the tap, taking a shower, doing laundry, or doing a load of dishes. The amount of time to run the water will depend on whether your home has a lead service line or not, as well as the length and diameter of the service line and the amount of plumbing in your home.

- Have your water sampled. Contact a certified laboratory to have your water tested for lead. A list of certified laboratories is available on EPA's website. Note, a water sample may not adequately capture or represent all sources of lead that may be present. For information on sources of lead that include service lines and interior plumbing, please visit https://www.epa.gov/ground-water-and-drinking-water/basic-information-about-lead-drinking-water#getinto.

Ongoing Efforts to Determine Unknown Pipe Materials

The City of Hendersonville is actively conducting field verifications to determine pipe materials. A statistical approach, involving a random sample of over 340 locations representing the entire distribution network, is underway. Our utility is committed to meeting/exceeding the EPA Standard for ensuring utility and customer- owned pipes are lead free.

Determining the Material of Your Service Line

To identify the material of your service line, consult a licensed plumber or Visit Protect Your Tap: A Quick Check for Lead, the EPA’s step-by-step guide.

Completed Inventory Work to Date

The City of Hendersonville has completed an extensive records review and identified areas most likely to contain lead. These areas have been excavated and confirmed to contain non-lead pipe materials. Historical inventory records from 1929–1969 show no recorded use of lead pipes as a utility pipe material, further suggesting that lead was not commonly used in our service lines.

Contact us at serviceline@hvlnc.gov

If you have questions, comments, or information to help us better describe your service line, please contact us at serviceline@hvlnc.gov.